When it comes to transporting cargo in the United States there are many options to keep your cargo secured safely. However, custom-made tie-down straps are one of the most popular and safest solutions for keeping your cargo safely secured in place throughout transit.

The main reason custom-made tie-down straps have become so popular is due to the straps are tailored to your specific cargo application securement needs. The added customization from the tightening mechanism hardware, heavier-duty webbing blends, end-fitting hardware, and the overall length of the strap can easily be paired up to match the load and securement application.

In this blog post, we will go over the advantages of using custom-made tie-down straps and some of the many different customization options available. Let’s begin.

The Different Webbing Customization Options for Custom Made Tie Down Straps

Polyester tie-down webbing is the most common blend for any tie-down securement application due to its heavy-duty strength, little stretching, and ultimate durability. It also has durability benefits such as helping prevent mold, mildew, moisture resistance, and resistance to the sun’s UV rays which could cause damage to your straps over time while being outside in the elements.

Polyester tie-down webbing comes in several different widths of webbing ranging from 1-inch, 2-inch, 3-inch, and 4-inch wide. In general, the wider the tie-down strap is the more material it uses and the heavier-duty breaking strength and working load limit rating. This can also be applied to light-duty webbing blends, standard-duty webbing blends, and heavy-duty webbing blends that use more layers of material.

For example, a 1,500 lbs breaking strength 1-inch wide polyester tie-down webbing would be considered the light-duty blend, and a heavy-duty 1-inch wide polyester webbing blend features a 6,600 lbs breaking strength. This is due to more layers of material and a heavier-duty stitching pattern to help ensure heavier cargo remains secured throughout transit.

How to Build A Custom Made Tie Down Strap

Ratchet Straps USA is located in the United States and offers full customization to almost all of our ratchet straps, cam buckle straps, winch straps, and more. Custom Tie tie-down straps begin with selecting a width of webbing that pairs with the weight of your cargo.

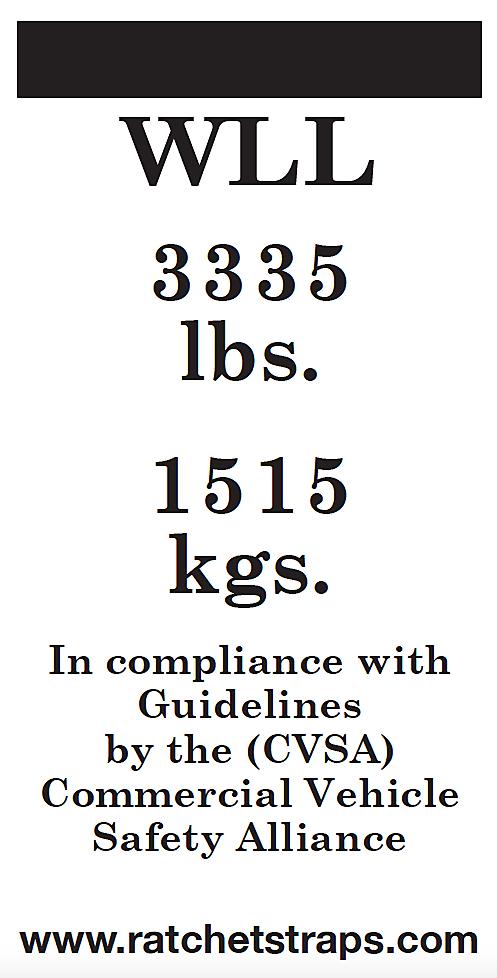

For example, if your cargo weighs 1,500 lbs you would want to go with a strap that exceeds that weight in the safe working load limit rating and for added safety to ensure you are using multiple tie-down straps in case a strap is to break or the load was to shift during transit from a hard brake, sudden lane change, or a fast acceleration. In this instance, you would want to use our heavy-duty 2-inch wide polyester tie-down webbing and heavier-duty hardware selections to provide a safe assembly working load limit of 3,335 lbs per strap.

Although the standard duty webbing may be capable of tackling the securement application you want to ensure you exceed the working load limit of the weight of your cargo as a safety net to prevent potential damage to your cargo and other motorists. The heavier-duty webbing also tends to last longer as friction burns and sharp edges are the number one causes of tie-down strap failure it offers more protection compared to lighter-duty webbing blends to ensure high levels of safety.

Next, you will want to decide if you want to tighten the strap into place using a ratchet hardware that flows in one direction and provides great strength and load security, a cam buckle that is tightened by the ultimate amount of hand strength, or by an installed winch for flatbed trailers that creates a cost-effective long term securement solution for professional flatbed truckers. Remember when you are building a strap to keep the working load limit and the weight of your cargo in mind.

Cam Buckle hardware may be ideal in certain cargo control applications, but it may also not be heavy-duty enough depending on the weight of your cargo. This may cause you to change to ratchet hardware or to use more straps to exceed the working load limit rating.

Once you have the tie-down webbing and the tightening mechanism selected you will want to choose the end-fitting hardware. Some of our end-fitting hardware includes anything from wire hooks, e-track fittings, flat hooks, bolt-down plates, floor anchors, chains and hooks, and more.

As tie-down straps are only as strong as their weakest link, pair end-fitting hardware with the target working load limit rating you are looking for. Some options may not meet the target working load limit rating you are looking for and may need a heavier-duty hardware option.

Once you have selected the webbing blend, the hardware to tighten the strap, and the end fitting you now will need to determine what color of polyester tie-down webbing you want for your securement application as well as the overall length of the strap.

There are two main lengths that you will need for most ratchet straps and other tie-down straps: the strap’s length on the short end of the strap that includes the ratchet and the overall length of the strap you are looking for. Typically the short end, also known as the fixed end ranges from 12 inches to 18 inches in most cases, but can be custom-made to any length.

The overall length of the strap is determined from one end of the strap to the other end. You can easily measure the length you are looking for by using a piece of string or yarn and measure the distance needed by using a tape measure. If you don’t find the exact customization option that you are looking you can reach our experts best by giving us a call at 800-483-2189 or by using our online contact us page located at the top of the website.

The Different Colors of Polyester Tie-Down Webbing

Once you have the hardware picked out it’s now time to decide what color of tie-down webbing to go with for your custom straps. This can be a personal preference based on the company’s colors, to make your sports car, to match your off-road ride, or based solely on it being your favorite color.

Choosing a different webbing color does not change the material breaking strength or working load limits. This is based solely on what color fits you and what your application needs the best. We have numerous colors ranging from Yellow, Black, Blue, Orange, Red, CAMO, Olive Drab, Purple, Light-Blue, Green, White, and more. Not all of these colors are available for various sizes and may have more or fewer colors depending on the size and strength of the webbing.

Due to the manufacturing dying process of polyester tie-down webbing colors may vary slightly due to the webbing material strength as more or less dye may be required. To see the best comparisons of the true colors of tie-down webbing please view our tie-down webbing rolls section by clicking HERE.

Tie Down Strap Safety Tips and Guidelines

• Inspect Your Tie-Down Straps Regularly – Before and after every use of using tie down straps you should always look over your tie-down straps for any potential damage they have received while in use or while in storage between usage. Some things to look out for include wear and tear, cuts in the webbing, fraying to the webbing, or other damage to the hardware or the strap. While it is very rare ensure that the hardware is also in good condition such as hooks, ratchets, or cam buckles for any defects, bends, corrosion, or other visible damage.

• Securing Loose Ends of the Strap – Make sure always to secure any loose ends of the tie-down straps to prevent them from flapping around in the wind during transit as this can cause the straps to receive damage from fraying or friction burns causing the strap to be repaired or replaced over time.

• Avoid Overloading the Straps Load Capacity – Remember to always follow the strap working load limit rating tag that is sewn onto the strap and avoid exceeding this limit. Exceeding the limit can cause the strap to fail or become damaged causing a potentially dangerous situation while going down the road. You can view our full blog post on How to Understand Working Load Limits for further information on how to stay safe.

• Make Sure Tie-Down Straps Are Tightened Properly – Ensure that the tie-down straps you are using are tightened securely to help prevent any movement during transit that otherwise could cause your cargo to move out of place. You also want to make sure not to overtighten your straps as it can cause the strap or the cargo you are securing to become damaged. You will want to make sure the strap is snug if using ratchet straps and apply 2 to 3 additional clicks of the ratchet in most cases based on your best judgment.

You can view the full Cargo Securement Rules in place by the Federal Motor Carrier Safety Administration by clicking HERE.

Frequently Asked Custom Tie Down Strap Questions

What is the longest length a custom strap can be? – Custom tie-down straps can be made in over 100 feet of webbing with the limiting length being around 150 feet long for most blends of webbing. This ultimately will depend on the application securement needs you are looking for and a very uncommon size for most applications. If you need a length longer than the listed lengths you see on our website you can reach our experts at 800-483-2189 or by using our online Contact Us form for further information.

Are Custom-Made Tie-Down Straps More Expensive? – Ultimately, it depends on the labor and materials needed for the strap. At Ratchet Straps USA we make a large portion of our tie-down straps in-house at our location in Bellville, Ohio which allows us to keep prices much lower than our competitors for custom straps. However, the heavier-duty tie-down webbing options help the straps last longer, and having a strap that fits your exact application needs can be very beneficial.

Are Cam Buckle Straps or Ratchet Straps Better? – Typically ratchet straps are the heavier-duty and more rigid option as the ratchet hardware flows in one direction and has a much heavier-duty working load limit rating. However, cam buckle straps are ideal when you are securing cargo that is fragile, antiques, expensive, and not extremely heavy in weight due to the straps being tightened by hand strength.

This helps cam buckle straps reduce the chances of damage from overtightening which can easily happen if you are not paying attention with ratchet straps. You can view our full guide on The Differences Between Ratchet Straps and Cam Buckle Straps in our blog post that breaks down which option is best for your cargo securement application.