What are Tie Down Straps?

Tie Down Straps is known around the professional shipping industry as the general name for various different types of cargo securement straps or cargo straps for short. Inside the tie-down straps umbrella, you can find different types of straps such as ratchet straps, cam buckle straps, or winch straps to name a few of the many different types of tie-down straps.

Tie Down Straps were designed with cargo securement in mind in order to help keep yourself and other motorists on the roadways safe. Tie Down Straps come in a wide variety of different widths of tie-down straps ranging from 1 inch for the lighter-duty type of securement applications to the heaviest duty straps using 4-inch wide webbing. Tie Down Straps are designed to keep cargo in place which is the reason behind polyester tie-down webbing being the webbing of choice as it provides great amounts of strength and a very little amount of stretching.

Stretching that occurs when securing cargo can easily cause your strap to come undone or your cargo to move out of place. It’s extremely important that you only purchase reputable tie-down straps that use polyester webbing as it is the safest way to transport any form of cargo. One of the added benefits of using a webbing blend such as polyester webbing is that the webbing is durable while being outside in the elements such as rain, snow, sleet, strong gusts, extremely cold weather, and extremely warm weather.

Polyester Webbing also is great for being extremely durable and protecting against the sun’s direct ultraviolet light which over time could wear down other types of webbing as well as help prevent mold and mildew. These are a few of the many factors that could determine the outcome of how long you should expect your tie-down straps to last and things to watch out for when you intend on storing tie-down straps in-between use.

You can view our full guide on how to store tie-down straps properly in our blog post HERE.

The Main Different Types of Tie Down Straps

Ratchet Straps – Ratchet Straps are by far the most common type of tie-down strap sold inside the United States due to their heavy-duty strength and durability over time. The way that Ratchet Strap work is by having the Ratchet Buckle hardware flow in one direction which allows the tension from the webbing to only be tightened without the risk of the cargo coming untightened during a move.

Once the desired slack is removed out of the tie-down webbing by using the ratchet buckle hardware is near impossible for the ratchet strap to come undone while on the road once the ratchet hardware is closed. Once you arrive at the next destination simply open the ratchet handle by pulling upwards on the lever and the webbing will quickly come undone and ready for you to store for the next time you need to use a ratchet strap.

Cam Buckle Straps – Cam Buckle Straps are most commonly used by professional movers and first-time shippers due to their ability to quickly tighten cargo down with an extremely friendly-to-use design. Cam Buckle Straps are tightened by the amount of strength that you can pull the webbing through the cam buckle which helps to prevent cargo from potentially becoming damaged from overtightening. Once the desired strength is reached simply let go of the cam buckle hardware opening and the webbing is held in place by the cam buckle hardware.

This is a great strap for those more sensitive, fragile, or valuable types of cargo to ensure they do not become damaged during transit. Another added benefit to using Cam Buckle Straps is they are much more cost-effective in most circumstances as they do not use as much hardware as traditional ratchet straps which help keep them affordable.

Flatbed Winch Straps – Flatbed Winch Straps are similar to Ratchet Straps and Cam Buckle Straps but are used for flatbed trailer securement applications. Winch Straps are made with the same polyester tie-down webbing as cam buckle straps and ratchet straps and are just as heavy-duty and durable. The main difference is winch straps do not have any ratchet hardware or cam buckle hardware in order to be secured.

Winch Straps are tightened along the rub rails of the flatbed trailer they use no Ratchet Hardware in order to tighten them. This allows for replacement winch straps to be purchased for around one-third of the price of comparison 4-inch ratchet straps that are used for flatbed trailers which makes them desirable by professional flatbed drivers.

Application Based Types of Tie Down Straps

Application-based types of tie-down straps are often specifically designed to fit the measurements, cargo securement needs, or designed to be an easier choice to find the tie-down strap that you need. This can range from anything such as bundling cargo together, hauling a vehicle down the road or setting up a canopy tent for a graduation party. Here are a few of our most popular different types of application-specific tie-down straps.

E Track Straps – E Track Straps come in two different types with one being E Track Ratchet Straps and the other being E Track Cam Buckle Straps. E Track Straps are designed to quickly latch into e-track rails that are installed horizontally or vertically on the walls and flooring of the enclosed trailers to create various securement points along the rail.

In doing such this makes those who ship various different types and sizes of cargo often able to find a securement point quickly along the rail. This helps to maximize the available amount of space inside of the trailer to ensure you are saving the need for multiple trips in a move or in order to deliver cargo to a customer across the United States.

One unique fact about E Track Straps is the length of webbing is color coded. Yellow webbing is known around the industry as 12’ in length, Gray as 16’ in length, and Blue webbing as 20’ in length. This helps those who ship different sizes of cargo to quickly identify if they are going to have a long enough strap to secure their cargo or if they need to use a different-sized strap to get the job done.

Hunting Straps – Hunting Straps are designed for use with Treestands and Hunting Applications such as Treestand Ladders. As the old sang goes “a safe hunt, is a successful hunt” and when safety is the number one priority purchasing reputable straps while being high up in trees in the woods is a must. RatchetStrapsUSA offers heavy-duty strength and durability that helps ease you with peace of mind knowing your treestand will remain safe during your hunt as long as the working load limits are being followed for your hunting strap.

Automotive Tie Down Straps – Automotive Tie Down Straps or Car Tie Down Straps provide great safety and strength for anyone securing a vehicle to be transported across town or to the next car show across the country safely. Our Automotive Straps are made to provide extremely heavy-duty durability and strength to ensure very little stretching occurs to help prevent your straps from breaking and keep your vehicle secured safely in place.

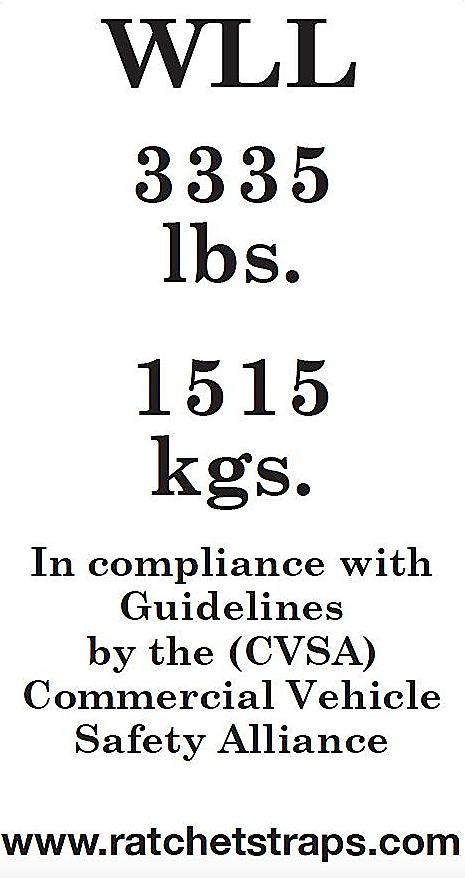

Our Car Tie Downs feature up to a 3,335 lbs Working Load Limit per strap to help ensure most makes and models can remain safe during transit. We also have a wide selection of custom-made car tie-down straps if you don’t find exactly what you are looking for on our website. If you don’t find exactly what you are looking for give our custom tie-down experts a call at 800-483-2189 or by using our online contact us form located at the top of the website.

Motorcycle & ATV Tie Down Straps – Motorcycle and ATV Tie Down Straps are an extremely important tool for those securing anything from a motorcycle, ATV, or UTV for transport. These straps are specifically designed to help secure your sweet rides during transit to ensure that it arrives in the same condition that it was secured in.

It’s important to always make sure that you are always using more tie-down straps than needed when securing vehicles in case a strap were to fail your ride would not become damaged. Have any questions or need it completely custom-made? Give our experts a call today at 800-483-2189 or by using our online contact us form located at the top of the website if you prefer email.

Endless Loop Straps – Endless Loop Straps as the name implies are completely endless and do not have any end fitting hardware such as hooks, e-track fittings, rings, or attachments. Endless Loop Straps loop back to themself and are tightened to bundle items together or hold items in place such as a moving blanket protecting a sensitive surface on a table during a move to a new house. Endless Loop Straps are also commonly used for hunting treestand applications, bundling cargo to pallets in manufacturing locations, and used to keep lids secured on crates.

Tent Straps – Tent Straps are designed to secure party event tent rentals, graduation parties, outdoor weddings, and corporate event tents. One major thing to consider when purchasing tent straps is the weather can change often and more times than not quickly, as well. It’s important that you always use more straps than traditionally needed for other securement applications when you are securing outdoor large tents for guests as strong wind gusts are known to cause havoc at times for those who are unprepared.

Our heavy-duty tent straps are made with our 1-inch and 2-inch-wide white polyester webbing and are meant to provide the heavy-duty strength that is needed when it comes to securing large outdoor tents with a variety of different securement options to fit all scenarios.

Odds are if you don’t find the perfect strap you are looking for to secure tent rentals with we can custom-make the perfect tent strap for you at an additional cost. If you are interested in learning more give our tie-down experts a call at 800-483-2189 or by using our online contact us form located at the top of the website.

How to Understand a Working Load Limit

Working Load Limits are determined by the breaking strength of the strap or otherwise the ultimate amount of force before the strap were to fail and divided by three. This allows you a two-thirds amount of wiggle room to accommodate for things that can’t always be measured such as another motorist slamming on the brakes in front of you, a sudden lane change, or a sudden acceleration from a stop. Working Load Limits were put into place to help keep motorists safe from the unknown that may happen when securing cargo on roadways.

An example of a Working Load Limit would be a 10,000 lbs breaking strength rated tie down strap would have an approximate 3,333 lbs working load limit. This would allow your tie-down strap to be safely rated at 3,333 lbs per tie-down strap and each additional strap used with having an additional 3,333 lbs working load limit.

If you have a vehicle that weighed 6,500 lbs we would always recommend at absolute minimum the use of four different ratchet straps in four different locations such as the front left, front right, rear left, and rear right to help prevent load shifts and keep your vehicle safe during transport. Tie Down Straps that do not have a sewn-on working load limit tag are at risk of potential fines from the Department of Transportation (DOT).

You can view our full guide on How to Understand Working Load Limits in our full blog post HERE.

How to Inspect Your Tie Down Straps for Damage

Tie Down Straps like most products have a product lifespan that can vary depending on the amount of usage that they receive as well as how they are taken care of when securing various types of cargo. The most common way that tie-down straps become damaged is the webbing receiving cuts or burns on the webbing from metal surfaces rubbing against the webbing. This is one of the main reasons why you will always want to try your best to avoid sharp metal surfaces.

Those who are not shipping weekly or monthly can typically expect their tie-down straps to last 2 to 5 or more years on average depending on usage and how they are stored. Those who are shipping daily or several times a week can likely expect a lower amount of time for the straps to last from repetitive use. If you have any questions about how to inspect your ratchet straps check out our full blog post HERE.